Have you ever seen a clinic visit slow down because the bed won’t adjust, squeaks, or feels unstable? That single piece of Patient Examination Furniture can change the whole workflow.

Examination Beds: Specifications, Materials, and Clinical Use Cases is a practical guide to what matters when you’re buying: specs, materials, safety, hygiene, and where each type fits clinically.

In short, the right examination bed is stable, easy to clean, comfortable for patients, and matched to your specialty needs—this is the approach we follow at trust medi.

What Are Examination Beds?

Examination Beds are clinical furniture designed for patient assessment, basic procedures, and short-duration positioning—not long-term inpatient care. You’ll also hear them called Medical Examination Beds, Clinic Examination Beds, or sometimes Hospital Examination Tables (especially when the design is flat and procedure-focused).

Unlike ward beds, examination beds are built for:

- Quick patient on/off movement

- Frequent surface disinfection

- Position changes for clinician access (backrest, leg section, height)

- Accessories like stirrups, paper roll holders, side supports, or armboards

They sit in the middle ground between “simple couch” and “procedure platform,” which is why specs and materials matter more than many buyers expect.

Why Examination Beds Are Essential In Clinical Settings?

In daily practice, examination beds support three things clinics and hospitals care about:

- Clinical access

A clinician needs stable positioning, correct working height, and predictable movement. That’s why Adjustable Examination Beds are common in busy rooms and specialty clinics. - Patient flow

If staff can clean fast, adjust fast, and move patients safely, appointments run on time. This is the quiet value of good Healthcare Examination Equipment. - Patient confidence

A wobbling frame or torn upholstery makes patients uneasy. A comfortable surface and safe step-in height reduce anxiety and help cooperation during exams.

For decision-makers, these beds are part of Clinical Furniture Solutions and Medical Furniture For Clinics—they affect experience and efficiency, not just room appearance.

Types Of Examination Beds Used In Healthcare

There isn’t one “best” bed—there’s a best fit per use case. Common types include:

- Fixed-height examination couches: simple, cost-effective, fewer moving parts

- Height-adjustable electric beds: ideal for staff ergonomics and safe transfers

- Hydraulic examination beds: adjustable without electricity, useful where power is unreliable

- Backrest-only adjustable models: good for general consult rooms

- 3-section/4-section models: allow more positioning for procedures and specialty exams

- Gynecology/OB examination beds: with leg supports, stirrups, and pelvic design

- Bariatric examination beds: wider platforms and higher load ratings

- Pediatric-friendly exam beds: safer edges, easy cleaning, calmer design

If you’re sourcing Examination Beds For Hospitals, you’ll often mix models across departments rather than standardizing a single design.

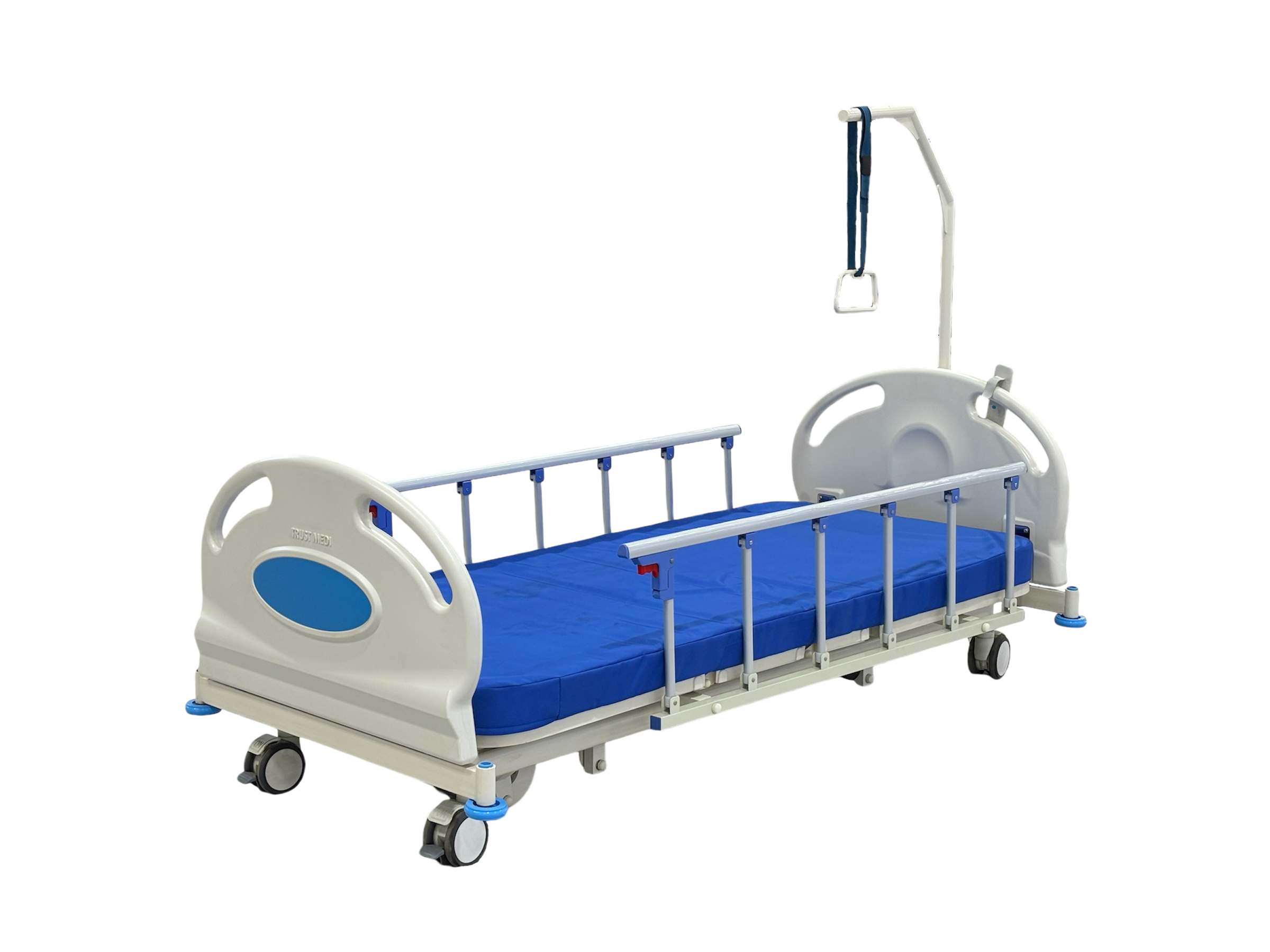

Key Specifications Of Medical Examination Beds

Buyers often ask for “a strong bed,” but you need measurable requirements. These are core Medical Bed Specifications to check:

Adjustment & movement

- Height range (especially if you do transfers from wheelchairs)

- Backrest angle range

- Trendelenburg/reverse Trendelenburg (if required)

- Head/leg section adjustments (manual or powered)

Dimensions & ergonomics

- Length and width of the mattress platform

- Low entry height (patient access)

- Clinician working height (to reduce back strain)

Mobility & stability

- Wheel diameter and quality

- Central locking vs individual brakes

- Anti-wobble frame design

- Leveling feet (for fixed units)

Power & controls (electric models)

- Actuator quality and smoothness

- Handset durability (sealed, easy to disinfect)

- Backup lowering option (manual override for safety)

Accessories

- Paper roll holder, side rails, armrests

- IV pole socket, oxygen cylinder holder

- Stirrups, leg holders, side supports

- Drawer or under-shelf storage

A helpful tactic in procurement is to request a compliance sheet mapping your room needs to the bed’s specs—this saves time for both the buyer and the Examination Bed Supplier.

Materials Used In Examination Bed Manufacturing

Examination Bed Materials determine lifespan, cleanability, and how the bed looks after thousands of wipe-downs.

Frame materials

- Powder-coated steel: common, cost-effective, durable when coating quality is high

- Stainless steel: strong corrosion resistance, favored in high-humidity or aggressive cleaning environments

- Aluminum components: lighter parts, often used in sections or accessory rails

Upholstery & padding

- Medical-grade vinyl / PU upholstery: designed for frequent cleaning and fluid resistance

- Multi-layer foam: comfort plus shape retention

- Seam style (stitched vs welded): welded seams can reduce fluid entry points

Surface details

- ABS or molded plastic covers for corners and moving parts

- Rounded edges and sealed joints to support cleaning

A good Examination Bed Manufacturer will specify not only “steel + vinyl,” but the coating system, thickness approach, and cleaning compatibility guidance.

Durability And Load Capacity Standards

Durability isn’t a marketing word—it should be documented. Focus on:

- Safe Working Load (SWL): the maximum safe load including patient and applied forces

- Static vs dynamic load: lifting/adjustment adds stress beyond a still load

- Cycle testing: how many raise/lower cycles the mechanism can handle

- Caster endurance: locking performance over time

- Upholstery wear resistance: cracking, peeling, seam failure

A practical approach for hospitals: define SWL based on your patient population and keep a margin for staff leaning, accessories, and procedure pressure. For clinics, you can match the risk profile, but don’t underbuy—cheap frames become expensive fast.

If you have internal policies tied to Medical Furniture Standards, ask suppliers to show their test approach and warranty coverage that matches the expected duty cycle.

Safety And Patient Comfort Features

Safety is not “extra.” It’s part of usability.

Key safety features

- Stable base geometry to prevent tipping

- Reliable braking and lock indicators

- Pinch-point protection around moving linkages

- Emergency stop/override for electric movement (where relevant)

- Non-slip step options for higher beds

- Rounded corners and protected edges

Comfort features that actually matter

- Foam density that supports without “bottoming out”

- Upholstery that doesn’t feel sticky after disinfection

- Quiet adjustment movement (patients notice noise)

- Headrest/arm support options for longer exams

When buyers compare models, comfort can feel subjective. You can make it objective by asking for foam specifications, thickness, and real warranty terms for upholstery wear.

Hygiene And Infection Control Requirements

Examination beds sit in the “high-touch” category. Hygiene comes from design choices:

- Smooth, wipeable surfaces with minimal seams

- Covered mechanisms that reduce dust and splash retention

- Fluid-resistant upholstery with sealed edges

- Removable sections where deep cleaning is needed

- Compatibility with common hospital disinfectants

In procurement, ask for a cleaning guide: approved chemicals, contact times, and what to avoid (some harsh agents shorten upholstery life). Good Healthcare Examination Equipment should stay clean without becoming fragile.

Examination Beds For Different Medical Specialties

Your specialty should drive your configuration:

- General practice / internal medicine: simple adjustable backrest, paper roll holder, storage shelf

- Emergency / triage: robust frame, quick clean surfaces, strong casters, higher SWL

- Gynecology/OB: stirrups/leg supports, cut-out options, stable pelvic area

- Dermatology: patient comfort for longer positioning, headrest control

- ENT: adjustable head support, clinician access around head area

- Orthopedics: strong platform, stable positioning, accessory mounts

- Dialysis or infusion assessment rooms: comfort-focused, arm support accessories

- Imaging prep areas: easy transfers, reliable height adjustment

This is why “one-size-fits-all” tends to disappoint. Matching use cases is the quickest way to protect your budget.

Examination Beds In Hospitals Vs Clinics

Hospitals and clinics buy the same category, but the priorities shift.

Hospitals typically prioritize

- High duty cycle durability

- Broader patient profiles, including higher SWL needs

- More accessories and multi-section positioning

- Strong documentation and service support

- Standardization across departments when possible

Clinics often prioritize

- Space efficiency and clean design

- Quick cleaning and fast adjustment

- Lower total cost without sacrificing safety

- Quiet operation and patient comfort

Both settings still need reliable performance, but the hospital environment punishes weak casters, thin coatings, and poor seam construction faster.

Compliance And Certification Requirements

Requirements vary by country and project type, but buyers commonly request:

- Manufacturer quality system information (often ISO-based)

- Product testing and safety documentation

- Materials and upholstery compliance details

- Warranty statements and service capability

- Traceable labeling, serial/model identification, and manuals

If you buy through tenders or large networks, documentation is often evaluated as heavily as the bed itself. A responsive Examination Bed Supplier will provide a clear technical dossier, not a single brochure page.

Factors Affecting Examination Bed Quality

Two beds can look identical in photos and perform very differently. Quality usually comes down to:

- Frame thickness and weld consistency

- Coating preparation (surface prep makes or breaks powder coat life)

- Actuator brand and installation (electric models)

- Caster grade and mounting quality

- Upholstery seam design and foam density

- Spare parts availability and local service support

- Real warranty coverage (what’s excluded matters)

Ask for a sample unit when possible, and test what staff actually do: brake lock, height movement, corner pressure, wipe-down behavior, and paper roll use.

Common Mistakes When Sourcing Examination Beds

Here are issues that cause regret later:

- Buying based on photos

You miss wobble, brake weakness, and poor seam finishing. - Ignoring height range

If nurses and doctors keep bending, you’ll hear about it quickly. - Underestimating cleaning impact

Some upholstery looks fine at delivery and fails after months of disinfection. - Not defining SWL clearly

Then the bed gets used outside its safe range. - Skipping service planning

If actuators or casters fail and parts take weeks, the room becomes unusable. - Overpaying for features you won’t use

Trendelenburg or complex sections can be wasted if your clinical workflow never needs them.

FAQ About Examination Beds

1) What’s the best choice: electric or hydraulic?

Electric is great for frequent height changes and busy workflows. Hydraulic works well when you want adjustability without relying on power. Your room volume and power reliability should decide.

2) Do I need stainless steel frames?

Not always. High-quality powder-coated steel can perform very well. Stainless is often chosen for aggressive cleaning conditions, humid environments, or where corrosion risk is high.

3) What SWL should I choose?

Pick based on your patient population and expected use. If your facility handles heavier patients or procedures that apply extra force, choose a higher SWL and confirm it is documented.

4) How do I compare upholstery quality?

Ask for the material spec, seam type, cleaning compatibility, and warranty terms for upholstery wear. Also check how it feels after a disinfectant wipe—some surfaces become tacky or crack over time.

5) Are examination beds and hospital beds interchangeable?

They serve different workflows. Examination beds are built for short-term positioning and frequent cleaning; inpatient beds are built for longer stays, repositioning, and additional safety functions.

Choosing the right examination bed is not about picking a popular model—it’s about matching specs, materials, hygiene design, and load capacity to the way your teams work every day. When you align Medical Bed Specifications with your specialty use cases, you reduce breakdowns, speed up patient flow, and improve comfort without adding complexity.

If you’re sourcing Medical Examination Beds for new rooms, replacements, or multi-site rollout, trust medi can help you shortlist models, compare documentation, and secure reliable supply and after-sales support—reach out with your department list and expected quantities to get a tailored recommendation.